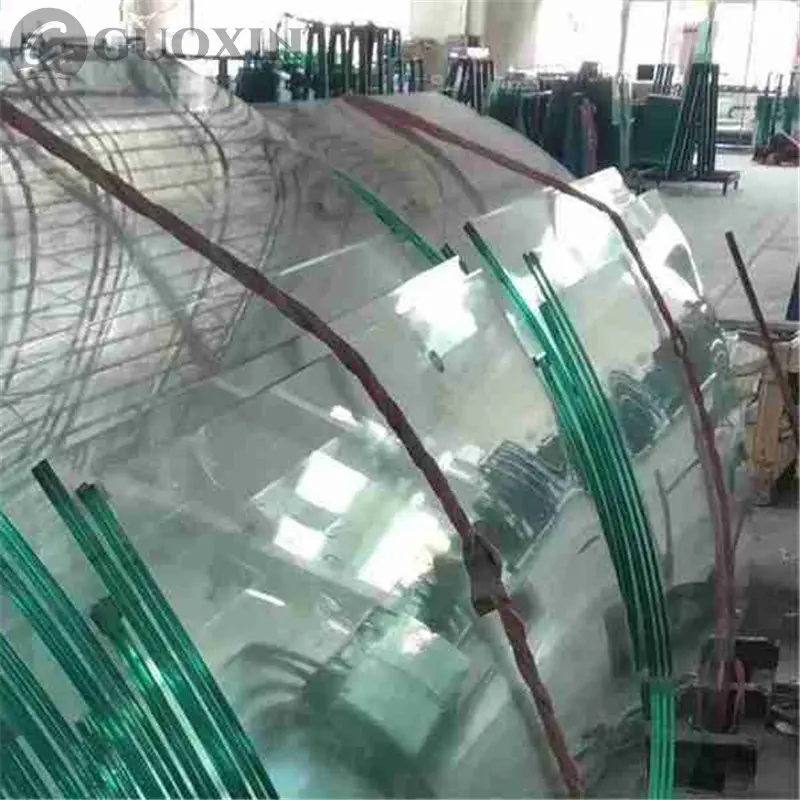

Curved Laminated Glass

The main advantages of Curved laminated glass

Curved laminated glass represents a groundbreaking innovation in architectural glazing, seamlessly combining the superior strength of tempered glass with the exceptional safety features of laminated interlayers. This advanced material offers unparalleled benefits for contemporary building designs, making it an increasingly popular choice among architects and designers worldwide.

Enhanced Structural Integrity

Through the precise combination of quenching and laminating processes, curved laminated glass achieves remarkable strength that surpasses conventional flat glass by 5-8 times as same specifications. Its curved configuration naturally provides greater load-bearing capacity, making it ideal for expansive glass facades and cantilevered structures.

Uncompromising Safety Performance

The PVB interlayer in curved laminated glass ensures that even when broken, glass fragments remain firmly bonded, eliminating dangerous shattering. This critical safety feature makes it perfect for skylights, glass walkways, and high-rise applications where fall protection is paramount.

Superior Design Flexibility

Available with bending radii from 800mm upwards, curved laminated glass can be customized to create stunning architectural features. The laminating process accommodates various interlayer options including colored, patterned, or even smart film interlayers for dynamic visual effects.

Excellent Weather Resistance

Engineered to withstand extreme temperature fluctuations (-40°C to 120°C), curved laminated glass maintains its structural integrity and optical clarity in diverse climatic conditions, outperforming standard curved glass solutions.

Improved Acoustic Performance

The vibration-damping properties of the PVB interlayer provide superior sound insulation (up to 50dB reduction), significantly enhancing acoustic comfort in urban environments and noise-sensitive applications.

UV Protection & Energy Efficiency

Curved laminated glass blocks 99% of harmful UV radiation while maintaining high visible light transmission. When combined with low-emissivity coatings, it contributes substantially to a building's energy efficiency.

product Specifications

| Processing thickness | 4mm~ 19mm |

| Maximum size | 3000mmx6000mm |

| Minimum size | 400mm x 600mm |

| Min Radius | 900mm for curved tempering process |

| Glass color | clear, ultra clear, grey, bronze, blue, green, etc. |

| Additional process | ceramic frit; coated; frosted; acid etched; etc |

| Transmittance | 8~85%. |

| Shape | curved. |

| Capacity | 2500SQM/DAY. |

| Curved glass types | Curved tempered glass, curved laminated glass, curved insulated glass, curved low e insulated glass, curved ceramic frit glass, curved fluted glass, curved pdic glass, etc. |

description2