Lightweight Insulating Glass OEM Solutions from Top Manufacturers and Suppliers

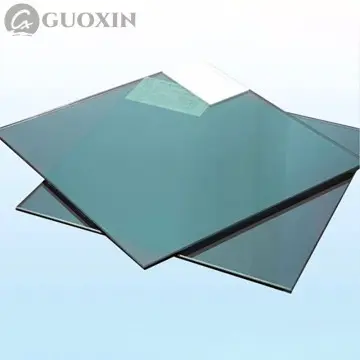

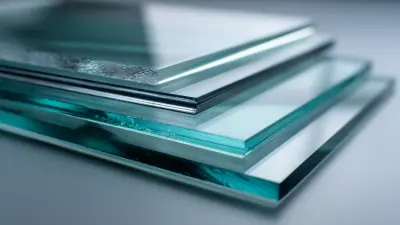

Sourcing high-quality lightweight insulating glass is essential for optimal performance and energy efficiency. Our product meets CE certification standards, guaranteeing compliance with stringent quality and safety requirements. This lightweight insulating glass provides exceptional thermal performance while minimizing installation weight and costs, making it an ideal choice for modern construction projects.

Key Methods For Lightweight Insulating Glass Guarantees Peak Performance Your End-to-End Solution

Lightweight insulating glass has emerged as a key player in the construction and manufacturing sectors, providing an exceptional balance of durability and energy efficiency. This type of glass not only meets rigorous performance standards but also significantly reduces the overall weight of structures, making it a preferred choice for architects and builders aiming for innovative design solutions. One of the most effective methods to ensure the peak performance of lightweight insulating glass is through rigorous product testing and certification. These steps guarantee that the materials comply with international standards, ensuring reliability in various environmental conditions.

Moreover, advanced manufacturing techniques are essential for optimizing the insulating properties of this glass. Techniques such as vacuum sealing and the use of specialized coatings can enhance thermal insulation, resulting in improved energy savings for buildings. By investing in state-of-the-art technology and innovative designs, manufacturers can meet the diverse needs of global buyers seeking high-performance materials.

An end-to-end solution for lightweight insulating glass encompasses everything from initial design to final installation. Collaborating with experienced suppliers ensures that each stage of the process contributes to the final product’s efficacy. Additionally, ongoing support and consultation can help procurement teams make informed decisions, enhancing both project outcomes and sustainability goals. With the construction industry continually evolving, adopting lightweight insulating glass represents a forward-thinking approach to modern building practices.

Key Methods For Lightweight Insulating Glass Guarantees Peak Performance Your End-to-End Solution

| Method | Description | Benefits | Performance Impact |

|---|---|---|---|

| Low-E Coating | A microscopically thin layer that reflects heat while allowing light to pass through. | Improved energy efficiency, reduced heating costs. | Increases U-value, enhances insulation performance. |

| Argon Gas Filling | Inert gas filled between panes to reduce heat transfer. | Enhanced thermal insulation, reduced condensation. | Lowers thermal transmittance, improves R-value. |

| Spacer Bar Technology | Utilizes thermally efficient materials to separate the glass panes. | Prevents thermal bridging, reduces heat loss. | Enhances overall glazing performance. |

| Triple Glazing | Three panes of glass providing superior insulation. | Maximum thermal performance, excellent noise reduction. | Significantly increases energy efficiency ratings. |

Step-by-Step Guide To Lightweight Insulating Glass Winning in 2025 Outperforms the Competition

J

Jessica Taylor

Quality beyond compare! The service staff was professional and went out of their way to assist me.

26

June

2025

A

Alexander Perez

Great product quality! The service team is always ready to lend a hand.

15

June

2025

R

Ryan Baker

Immaculate product details and functionality. The team’s dedication to service is evident.

27

June

2025

S

Sophia Collins

Impressive quality! The service representatives were very knowledgeable.

31

May

2025

S

Sophie Garcia

Incredible craftsmanship! The service staff were clearly well-trained.

01

June

2025

E

Elijah Phillips

Superb product performance! The after-sales service was very competent.

06

July

2025