Can Low-E Insulated Glass Help the Construction Industry Achieve Its "Dual Carbon" Goals?

Introduction: The Climate Imperative and Glass Industry Transformation

The global construction sector makes up nearly 40% of energy-related carbon emissions, and building envelopes—especially windows and facades—are key to how well buildings retain or lose heat. As countries push to meet the “dual carbon” goals—hitting peak carbon emissions by 2030 and achieving carbon neutrality by 2060—demand for advanced glazing solutions has spiked. Low-E insulated glass stands out here as a go-to solution: it pairs low-emissivity coatings with multi-pane insulation to cut down on energy use.

In this article, we’ll look at how Low-E insulated glass is changing the game for building sustainability. We’ll also cover how it works alongside other advanced options—such as reflective insulated glass and tempered insulated glass—and how it could speed up the world’s shift to net-zero buildings.

The Science of Low-E Insulated Glass: How It Works

Low-E (low-emissivity) insulated glass units (IGUs) consist of two or more glass panes separated by a sealed airspace filled with inert gas (argon or krypton). The critical innovation lies in the microscopic metallic or metal oxide coatings applied to one or more glass surfaces. These coatings reflect infrared radiation while allowing visible light to pass through, creating a thermal barrier that minimizes heat transfer.

Key Mechanisms:

Thermal Insulation: The coated glass reflects up to 90% of long-wave infrared radiation, reducing winter heat loss by 50–70% compared to single-pane windows.

Solar Control: Advanced coatings block 70–85% of solar heat gain, mitigating cooling loads in hot climates.

UV Protection: By filtering 95–99% of harmful ultraviolet rays, Low-E glass prevents furniture fading and protects occupant health.

When paired with glazing insulated glass systems—which optimize pane spacing and gas fill for maximum thermal resistance—the energy savings become even more pronounced. For example, triple-pane Low-E IGUs with krypton gas can achieve U-values (thermal transmittance) as low as 0.15 W/m²K, approaching the performance of walls.

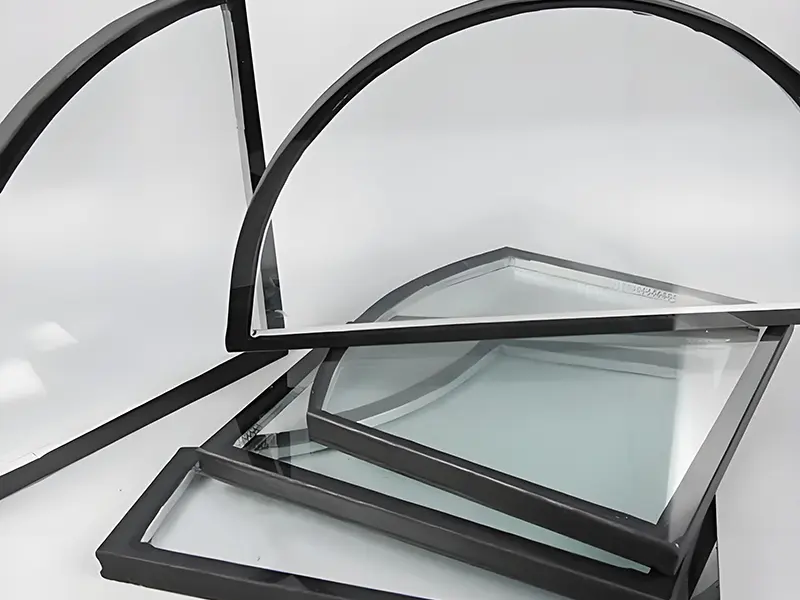

Reflecting Insulated Glass: A Synergistic Technology

While Low-E glass focuses on emissivity control, reflecting insulated glass enhances performance through high-reflectivity coatings. Typically used in tropical regions or large-scale glass buildings (e.g., curtain walls), these units incorporate metallic layers that bounce back up to 90% of solar radiation.

Combining Low-E and Reflecting Technologies:

Climate Adaptability: In hot climates, reflecting coatings reduce solar heat gain, while Low-E layers prevent conductive heat loss. This dual action cuts HVAC energy use by 30–50%.

Aesthetic Flexibility: Reflective glass can be tinted or patterned to meet architectural design requirements without compromising efficiency.

Durability: When integrated into tempered insulated glass—a safety glass strengthened through thermal or chemical processes—the result is a product resistant to thermal stress, impact, and seismic forces.

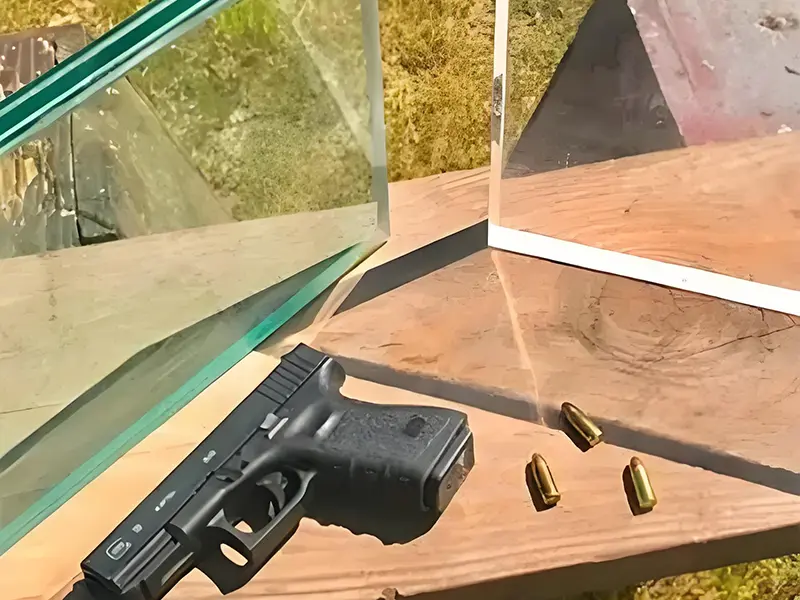

Tempered Insulated Glass: Strength Meets Sustainability

Safety and energy efficiency are not mutually exclusive. Tempered insulated glass combines the thermal benefits of Low-E coatings with the structural integrity of tempered glass, which is four to five times stronger than annealed glass.

Advantages:

Thermal Resistance: Tempered glass withstands rapid temperature changes, making it ideal for facades exposed to direct sunlight or cold climates.

Impact Safety: In high-rise buildings or hurricane-prone regions, tempered IGUs resist breakage from wind-borne debris or accidental impacts.

Post-Breakage Safety: If shattered, tempered glass fractures into small, blunt pieces, reducing injury risks.

When laminated with polyvinyl butyral (PVB) interlayers, tempered Low-E IGUs also provide acoustic insulation and blast resistance, expanding their use in urban environments.

Market Growth and Global Adoption

The Low-E insulated glass market is projected to grow at a 6.5% CAGR from 2023 to 2032, driven by:

Regulatory Pressures: Over 60 countries have implemented energy efficiency standards for buildings, with the EU’s Energy Performance of Buildings Directive (EPBD) mandating near-zero-energy buildings by 2030.

Urbanization: By 2050, 68% of the global population will reside in cities, necessitating high-performance glazing to mitigate urban heat islands.

Cost Parity: Advances in manufacturing have reduced Low-E glass premiums to 10–15% above conventional glass, accelerating adoption in emerging markets.

Regional Trends:

North America: The U.S. Green Building Council’s LEED certification has spurred demand for Low-E IGUs in commercial projects.

Asia-Pacific: China’s "14th Five-Year Plan" allocates $1.4 trillion to green infrastructure, prioritizing energy-efficient glazing.

Europe: The EU’s "Renovation Wave" aims to upgrade 35 million buildings by 2030, creating a massive market for retrofit glazing solutions.

Challenges and Innovations

Despite its promise, Low-E insulated glass faces hurdles:

Cost Sensitivity: In price-sensitive markets, developers may opt for cheaper single-pane glass, undermining long-term savings.

Recycling Complexity: The metallic coatings in Low-E glass complicate recycling, though advancements in chemical separation are emerging.

Installation Expertise: Improper sealing of IGUs can lead to gas leakage, reducing thermal performance over time.

Cutting-Edge Solutions:

Vacuum Insulated Glass (VIG): By replacing gas with a vacuum, VIG achieves U-values below 0.5 W/m²K in ultra-thin profiles (6–12 mm), ideal for historic building retrofits.

Dynamic Glazing: Electrochromic or thermochromic coatings adjust tint levels in response to sunlight, optimizing daylighting and energy use.

AI-Driven Design: Machine learning algorithms now optimize glazing specifications (coatings, pane spacing) for specific climates and building orientations.

The Path to Carbon Neutrality

Low-E insulated glass is not a standalone solution but a critical component of a holistic sustainability strategy. When integrated with:

Renewable Energy: Solar-controlled glazing reduces peak demand for air conditioning, complementing rooftop PV systems.

Smart Building Systems: IoT sensors adjust shading and ventilation based on real-time thermal data, maximizing IGU efficiency.

Circular Economy Principles: Modular glazing designs enable easy replacement of damaged panes, extending product lifespans.

A 2024 study by the International Energy Agency found that widespread adoption of Low-E IGUs could reduce global building sector emissions by 8–12% by 2030, equivalent to removing 300 million gasoline-powered cars from roads.

Conclusion: A Clear Future

As the world confronts the dual challenges of climate change and urbanization, Low-E insulated glass stands as a testament to innovation’s power to reconcile human comfort with planetary health. By merging with reflecting insulated glass, tempered insulated glass, and emerging smart technologies, it offers architects and developers a versatile toolkit to achieve the "dual carbon" vision.

The journey ahead demands continued investment in R&D, policy support for green building codes, and consumer education on lifecycle costs. Yet, the evidence is unequivocal: Low-E insulated glass is not just a product but a pivotal enabler of a sustainable, resilient future.