Flat vs. Curved Glass: Which is More Cost-Effective for Your Project?

In architecture today, picking between flat and curved glass isn't just about looks. It's a big-time decision that hits your budget, how sturdy the building is, and what it's worth in the long run.

As more and more designs feature flowing, dynamic shapes, the need for high-performance curved glass is definitely growing. Now, let's discuss why it's a wise and cost-effective choice. We gotta look beyond that first price tag and think about what it's worth over time, what cool tech benefits it brings, and where it really stands out in a project.

For anyone leading a project—architects, developers, project managers—this is the core challenge: making sure your design vision doesn’t break the bank. It's no surprise then that the global market for curved glass is expected to grow significantly, as it becomes a go-to solution for everything from homes and offices to public buildings.

1. Initial Costs: Breaking Down the Price Difference

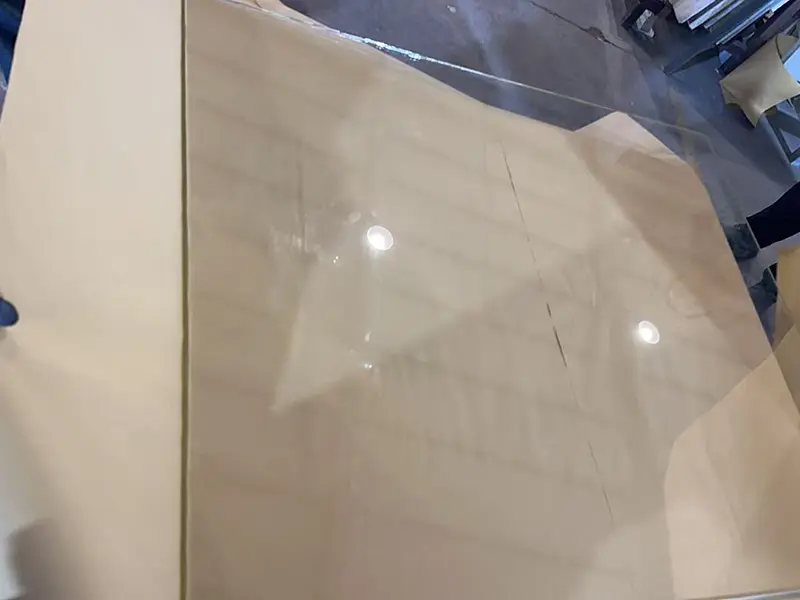

It's no secret that the initial invoice for curved bend sheet glass will be higher than that for its flat counterpart. Industry analyses consistently show that curved glass typically commands a premium of approximately 30% to 50% over flat glass . This price differential is rooted in a more complex and resource-intensive manufacturing process. Creating flawless curved glass requires specialized equipment, including high-temperature kilns for heat bending and precision molds, and involves stringent quality control measures to ensure optical clarity and structural integrity.

The production of curved glass windows, for instance, is not merely about bending a flat pane. It involves heating the glass to a specific temperature until it becomes pliable, then carefully forming it over a mold to achieve the exact desired radius without introducing distortions or internal stresses. This process requires significant expertise and energy input. Furthermore, the raw materials used may need to be of a higher grade to withstand the bending process without compromising strength or clarity. While flat glass manufacturing is highly optimized for mass production, curved glass production often involves a greater degree of customization, contributing to the higher initial cost. However, this is only one part of the financial equation.

2. The Long-Term Value and Performance of Curved Glass

When evaluating cost-effectiveness, the analysis must extend beyond purchase price to consider long-term value. Curved glass offers several performance advantages that can translate into economic benefits over the lifespan of a building.

Enhanced Structural and Environmental Performance: The inherent arched shape of curved glass often provides greater structural rigidity compared to flat glass of the same thickness. This can allow for larger, more ambitious glazing designs with reduced need for additional support structures, potentially simplifying the building envelope. In terms of environmental performance, modern curved glass can be fabricated as part of high-performance insulating glass units (IGUs), contributing to excellent thermal efficiency and helping to reduce a building's heating and cooling costs .

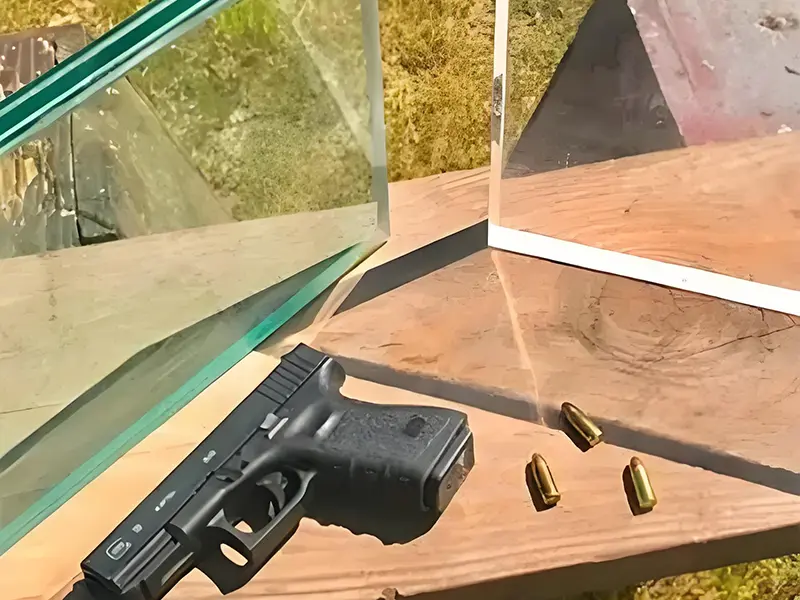

Durability and Low Maintenance: High-quality curved glass is subjected to tempering or heat-strengthening processes, making it significantly stronger than standard annealed glass. This enhanced durability translates to greater resistance to wind loads, thermal stress, and potential impacts, leading to lower maintenance and replacement costs over time. Its application in demanding settings, from high-rise facades to structural elements, underscores its long-term reliability .

3. Key Applications Where Curved Glass Delivers Superior ROI

The return on investment (ROI) for curved glass becomes particularly evident in specific applications where its unique properties solve design and functional challenges more effectively than flat glass.

Architectural Statements with Curved Glass Windows and Facades: For projects where creating a landmark identity is a priority—such as museum entrances, luxury hotel lobbies, or corporate headquarters—the visual impact of curved glass windows and curtain walls is unparalleled. The ability to create seamless, flowing forms can define a building's character, potentially increasing its property value and aesthetic appeal. The trend towards fluid architecture in contemporary design makes this a highly valued feature .

Innovative Interior Design: The Tempered Curved Range Hood Glass: In residential and commercial kitchens, the range hood is a focal point. Using tempered curved range hood glass combines safety with sleek, modern design. The tempering process ensures the glass can withstand high heat, while the curved profile allows for ergonomic designs that improve airflow and capture efficiency. This application demonstrates how curved glass merges functionality with high-end aesthetics in interior spaces.

Structural Elements and Skylights: Curved glass is increasingly used in stairs, balustrades, and skylights. In a frameless glass railing system, for example, the curved glass panels provide both safety and an unobstructed view, enhancing the sense of space . For skylights and arched ceilings, curved glass provides a graceful, weather-tight solution that floods interiors with natural light, creating unique spatial experiences that flat glass cannot achieve.

4. Making the Right Choice: A Project-Specific Checklist

Is curved glass the right choice for your project? The answer depends on a careful evaluation of your priorities. The following checklist can guide your decision-making process.

Opt for Curved Glass if your project prioritizes:

Iconic Aesthetics: When the architectural goal is to create a unique, visually striking landmark.

Fluid Design Language: When the design requires organic, non-rectilinear forms to achieve its spatial concept.

Performance in Specific Applications: For elements like sweeping facades, spiral staircases, or high-heat areas where the functional benefits of curved glass are essential.

Long-Term Value: When the decision matrix favors durability, energy efficiency, and low lifecycle maintenance over minimizing upfront costs.

Flat Glass may be more suitable if:

Budget is the Primary Constraint: The project has strict, non-negotiable budget limitations for the glazing package.

Design is Orthogonal: The architectural design is predominantly based on straight lines and right angles.

Standardization is Key: The project utilizes standardized, off-the-shelf window and door systems to accelerate timelines and control costs.

Conclusion: A Strategic Investment in Design and Function

The debate between flat and curved glass is not about finding a universal winner, but about matching the right material to the project's specific goals. While flat glass remains a cost-effective and excellent solution for countless applications, curved glass has cemented its role as a strategic tool for innovative architecture. Its higher initial investment is often justified by its unparalleled aesthetic appeal, superior performance in specific applications, and contribution to durable, energy-efficient building envelopes. By considering the total cost of ownership and the value of architectural distinction, project stakeholders can make a savvy, cost-effective choice that leverages the full potential of modern glass technology.

Jiangsu Guoxin Glass Co., Ltd. is a professional manufacturer of high-quality glass products, including insulated glass, tempered glass, and curved glass. With advanced manufacturing capabilities and a commitment to precision engineering, we provide tailored glazing solutions for architectural projects worldwide. Our expertise ensures that clients receive the optimal balance of aesthetics, performance, and value, whether their vision calls for the classic practicality of flat glass or the dynamic elegance of curved glass.