Innovative LowE Composite Fireproof Glass Enhances Safety at Hainan Government Building

Project Overview: Setting New Standards in Public Building Safety

The Hainan Provincial Government Building stands as a landmark of administrative excellence and architectural innovation. Recently, this iconic structure underwent significant safety upgrades with the installation of cutting-edge LowE composite fireproof glass from Jiangsu Guoxin Glass Co., Ltd. This project’s such a big step ahead when it comes to combining top fire protection tech (the cutting-edge kind) with energy efficiency for public buildings. The big renovation zeroed in on the building's main front, the atrium areas, and the key escape routes, where fire safety and keeping the heat in or out were top priorities.

Our technical team conducted extensive on-site assessments prior to specification, analyzing the architectural challenges particular to tropical coastal environments. The combination of high temperatures, elevated humidity levels, and exposure to salty air created unique demands for both fire resistance and material durability. The selected LowE composite fireproof glass solution successfully addresses these challenges while maintaining the building's aesthetic integrity and maximizing natural light penetration throughout the interior spaces.

Technical Specifications of the Installed Fireproof Glass System

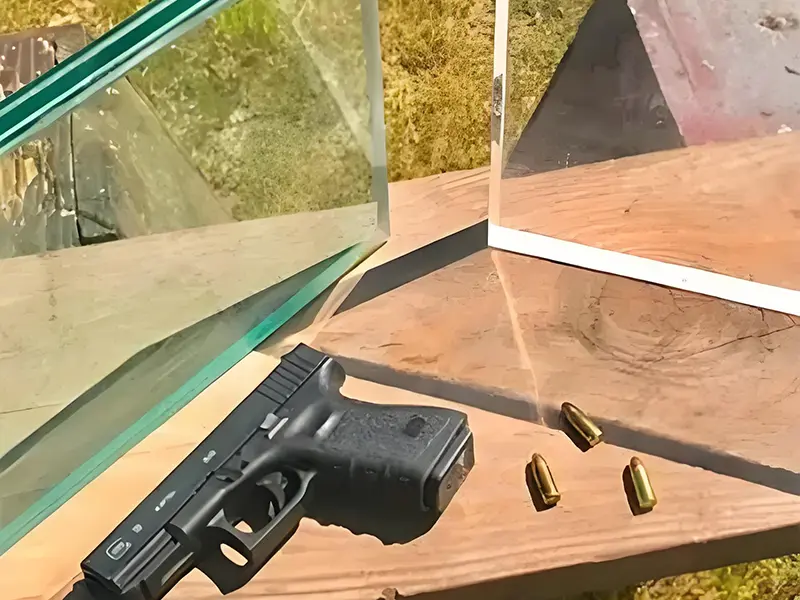

The LowE composite fireproof glass specified for the Hainan Government Building represents the pinnacle of fire protection technology. This specialized glass assembly consists of multiple laminated layers including transparent intumescent interlayers, low-emissivity coatings, and tempered glass panels. The system achieved a 90-minute fire resistance rating (FRR) while maintaining exceptional optical clarity. The total thickness of the assembly measures 33mm, comprising two 6mm tempered glass panels with a 21mm transparent fire-resistant gel interlayer.

The technical performance metrics exceed national standards for public buildings, with the glass demonstrating integrity and insulation stability during extended fire exposure tests. The installed composite fireproof glass maintains integrity at temperatures exceeding 850°C while the incident side temperature reaches 950°C. The low-E coating, applied through advanced magnetron sputtering technology, provides a shading coefficient of 0.45 and a U-value of 1.8 W/m²·K, significantly reducing solar heat gain and contributing to the building's overall energy efficiency.

The Science Behind LowE Composite Fireproof Glass Technology

Composite fireproof glass represents a sophisticated convergence of materials science and safety engineering. The fundamental principle involves creating a barrier that maintains structural integrity under extreme thermal stress while preventing heat transmission. When exposed to fire, the transparent intumescent interlayer undergoes a controlled chemical transformation, expanding to form an opaque, insulating barrier that blocks radiant heat transfer and contains the fire.

The integration of low-emissivity coatings adds another dimension of performance. These microscopically thin, virtually invisible metallic layers are deposited on the glass surface to create a selective filter for infrared energy. The coating allows visible light to pass through while reflecting medium and far-infrared waves, effectively reducing heat transfer through the glass assembly. This dual-function capability makes LowE composite fireproof glass particularly valuable in tropical climates like Hainan's, where both fire safety and thermal control are essential considerations.

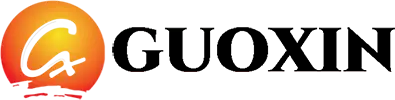

The manufacturing process involves precisely controlled lamination under heat and pressure, ensuring perfect bonding between layers without optical distortions. Each panel undergoes rigorous quality control testing, including standardized fire resistance tests, optical property verification, and structural performance assessments under various environmental conditions.

Why Composite Fireproof Glass Was Selected for This Project

The selection committee for the Hainan Government Building project identified several critical factors that favored composite fireproof glass over alternative solutions. Traditional wired glass or ceramic-based fire-resistant glasses presented limitations in optical quality, thermal performance, and design flexibility. The composite fireproof glass solution provided superior performance across all required parameters while offering additional benefits specific to the building's architectural requirements.

The transparent nature of the composite fireproof glass maintains visual connectivity and natural light transmission, which was particularly important for the building's open-plan design and atrium spaces. Unlike opaque fire barriers, the glass partitions allow for continuous visual monitoring of spaces while providing critical compartmentation. The material's weight-to-performance ratio enabled designers to create larger fire-resistant glazed areas without requiring excessive structural support modifications.

Furthermore, the composite fireproof glass system integrates seamlessly with other building systems, including smoke detectors, sprinkler systems, and emergency ventilation. The compatibility with framing systems allowed for both structural silicone glazing and conventional captured framing options, providing architectural flexibility while maintaining the required fire resistance ratings.

Installation Challenges and Technical Solutions

The installation process presented unique challenges that required innovative engineering solutions. The building's curved facade sections demanded precise cold-bending of the fireproof glass panels without compromising the integrity of the low-E coating or fire-resistant interlayers. Our technical team developed a specialized mounting system that allowed for the necessary curvature while maintaining uniform stress distribution across the glass surface.

Environmental conditions during installation required careful management, as the high humidity levels typical of Hainan's climate could potentially affect the adhesion properties of the interlayer materials. We implemented climate-controlled containment areas at the installation sites and used specialized sealing compounds compatible with both the glass system and the aluminum framing.

The integration of the fireproof glass with the building's existing curtain wall system required custom adapters and expansion joints to accommodate thermal movement while maintaining fire barrier continuity. Our engineering team worked closely with the facade consultants to develop transition details that preserved both the aesthetic continuity and the fire compartmentation requirements.

Performance Metrics and Safety Compliance

The installed LowE composite fireproof glass system meets and exceeds multiple national and international standards, including GB 15763.1-2009 for building safety glass, GB 50016-2014 for architectural fire protection design, and ISO 3009 for fire resistance testing methodology. Third-party testing verified the system's performance under rigorous conditions, confirming maintenance of integrity for 90 minutes during furnace testing.

Beyond the fundamental fire resistance requirements, the glass system contributes to multiple safety functions. The laminated construction provides enhanced impact resistance and remains intact even when the glass cracks, reducing injury risk from falling fragments during emergencies. The material also demonstrates excellent acoustic performance, achieving a Sound Transmission Class (STC) rating of 42, which significantly reduces noise transmission between compartments.

The energy performance metrics demonstrate the dual benefit of the LowE composite fireproof glass. Compared to conventional fire-rated glazing, the system reduces heat gain by approximately 35% while maintaining visible light transmittance of 72%. This performance contributes directly to the building's overall energy efficiency, reducing cooling loads and supporting the government's sustainability initiatives.

Jiangsu Guoxin Glass: Manufacturing Excellence in Fireproof Glass

As a leading manufacturer of specialized glass products, Jiangsu Guoxin Glass Co., Ltd. brings decades of expertise to the development and production of advanced fire protection glazing solutions. Our manufacturing facilities incorporate state-of-the-art processing equipment, including automated cutting lines, precision tempering furnaces, and clean room environments for lamination processes.

The production of LowE composite fireproof glass requires particularly stringent quality control measures. Each batch of raw materials undergoes thorough inspection, and the manufacturing process includes multiple checkpoints for dimensional accuracy, coating uniformity, and interlayer consistency. Our quality assurance system implements statistical process control methods to maintain consistent performance across production runs.

Research and development represents a core commitment at Jiangsu Guoxin Glass, with ongoing investment in new fire protection technologies and performance enhancements. Our technical collaboration with leading research institutions ensures continuous improvement of our composite fireproof glass products, particularly in the integration of energy-efficient coatings with fire-resistant properties.

The Future of Fire Safety Glazing in Public Architecture

The successful implementation of LowE composite fireproof glass in the Hainan Government Building project demonstrates the evolving landscape of fire protection technology in public buildings. The integration of multiple performance characteristics - fire resistance, energy efficiency, aesthetic quality, and environmental durability - represents the future direction of architectural glazing systems.

Emerging developments in composite fireproof glass technology include improved transparency retention at greater thicknesses, enhanced resistance to cyclic thermal stress, and integration with smart building systems for active fire response. The continuing evolution of low-E coatings promises even greater thermal performance while maintaining the critical fire protection properties.

As building codes increasingly emphasize both safety and sustainability, the demand for multi-functional glazing solutions like LowE composite fireproof glass will continue to grow. Jiangsu Guoxin Glass remains at the forefront of this technological evolution, committed to developing products that protect both people and property while contributing to architectural excellence and environmental responsibility.

The Hainan Government Building project stands as a testament to the successful application of advanced materials technology in creating safer, more efficient public spaces. The installation of our LowE composite fireproof glass has established a new benchmark for government building safety standards while demonstrating the practical benefits of integrating fire protection with energy conservation measures.

For more information about our comprehensive range of fireproof glass products, including composite fireproof glass, laminated fire-resistant glass, and insulated fireproof glass systems, please visit our website or contact our technical consultation team. Jiangsu Guoxin Glass Co., Ltd. remains committed to advancing glass technology for enhanced building safety and performance.