Is Laminated Glass Truly Expensive? Its Long-Term Value Will Surprise You

Laminated glass used to be seen as a high-end product, mostly used in special situations, but now it's slowly but surely becoming more popular in both the building and car industries. Recent industry analyses reveal the global laminated glass market reached .97 billion in 2024, with projections indicating growth to .83 billion by 2031, reflecting a 3.6% compound annual growth rate . Even though some people think it costs more upfront, when you really look into what it can do, its specs, and how much value it offers over its lifetime, it's clear why this stuff is now the go-to option for smart architects, builders, and property owners.

Beyond the Price Tag: Unpacking the Composition and Key Features

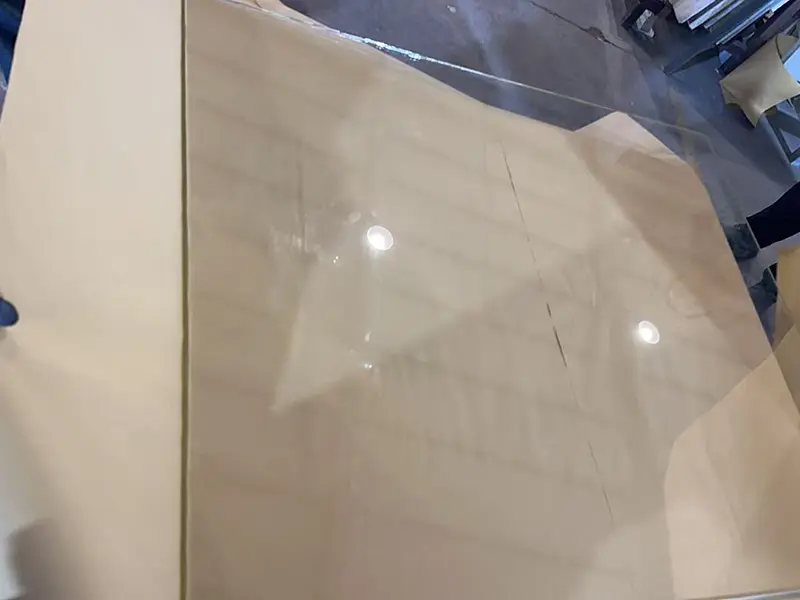

At its core, laminated glass is a composite material consisting of two or more glass plies bonded together with one or more layers of plastic interlayer, typically Polyvinyl Butyral (PVB), Ethylene-Vinyl Acetate (EVA), or advanced ionoplast polymers like SGP laminated glass . This sophisticated composition is achieved through a process of heat and pressure in an autoclave, creating a permanent bond that unlocks a suite of superior properties.

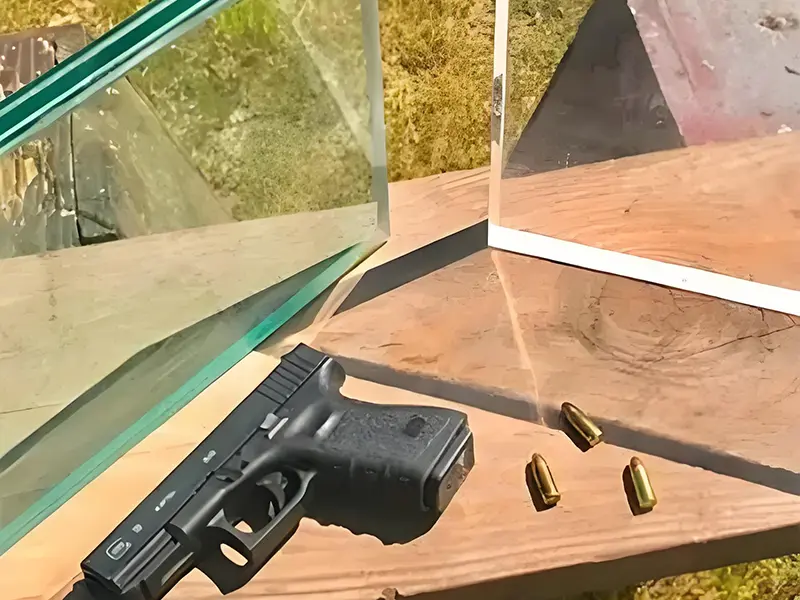

The most lauded characteristic is its exceptional safety and security performance. When impacted, the glass may crack, but the fragments adhere tenaciously to the resilient interlayer, preventing dangerous shattering and maintaining a protective barrier . This "fail-safe" characteristic is crucial for mitigating injury risk and deterring forced entry. Furthermore, the PVB interlayer acts as a superb sound dampener, significantly reducing noise transmission—a vital feature for urban buildings and offices located near high-traffic areas .

Another significant long-term value is UV protection. Standard windows offer little defense against the sun's damaging ultraviolet rays, which cause interior furnishings, artworks, and fabrics to fade. Laminated glass intercepts up to 99.5% of these harmful UV rays, preserving the value and appearance of interior assets and effectively saving property owners substantial sums in replacement costs over time .

Enhanced Structural Performance: Beyond basic safety, high-performance interlayers like SGP provide remarkable structural benefits. SGP laminated glass offers approximately twice the load-bearing capacity and five times the tear strength compared to standard PVB equivalents . This allows for more daring architectural designs, such as larger glass panels and glass structural elements, with reduced thickness, contributing to aesthetic and material savings.

Specifications and Versatile Forms: Meeting Modern Design Demands

The versatility of laminated glass is one of its strongest assets, allowing it to meet diverse aesthetic and performance requirements. It can be fabricated using various base glasses, including clear, tinted, low-iron (for enhanced clarity), and heat-strengthened or fully tempered glass for added strength and thermal stability .

Standard thicknesses for the glass plies range from 3mm to 19mm, with interlayer thicknesses typically at 0.38mm, 0.76mm, or 1.52mm for PVB, and 0.89mm or 1.52mm for SGP . This flexibility enables engineers to precisely tailor the specification to the specific needs of a project, whether for a standard window, a blast-resistant facade, or a overhead curved glass skylight.

The manufacturing process also accommodates complex shapes, making curved glass a viable and stunning architectural option. The production of curved laminates, especially using strong ionoplast interlayers like SGP, requires precise control during the heating and bending phases to ensure perfect conformity between the glass plies . The resulting products enable the creation of flowing, aerodynamic building forms and elegant sweeping balustrades that would be impossible with other materials.

For ultimate energy efficiency, laminated glass is often integrated into insulated glass units (IGUs). In this configuration, one pane of the IGU is a laminate, while the other might be a low-E coated glass, with an argon-filled air space between them. This combination delivers a powerful trifecta of safety (from the laminate), superior thermal insulation (from the IGU), and acoustic damping, representing a high-performance building envelope solution .

A Spectrum of Applications: From Essential Safety to Architectural Innovation

The application of laminated glass has expanded far beyond its origins in automobile windshields. Today, it is a critical component in numerous sectors:

Architectural Glazing: Its use in windows, doors, and particularly curtain walls is standard for safety and performance. It protects occupants from accidental falls and mitigates the risk of injury from storm-induced breakage .

Overhead and Structural Glazing: For skylights, glass roofs, bridges, and floors, the safety characteristic of laminated glass is non-negotiable. The high strength of SGP laminated glass makes it the material of choice for these structurally demanding applications, where broken glass must remain in place without significant deflection .

Balustrades and Barriers: Glass railings for balconies, stairways, and decks universally rely on laminated construction for obvious safety reasons, often specified with SGP for its superior stiffness and puncture resistance .

Security and Glazing: The ability to build up multiple layers of glass and interlayer creates a formidable barrier. This principle is used in bullet-resistant, blast-mitigating, and anti-intruder glazing for banks, embassies, and high-security residences .

Acoustic Control: Specialized acoustic PVB interlayers can be used to create effective sound barriers for buildings near airports, highways, or in noisy city centers, enhancing occupant comfort and well-being.

Demystifying the Cost: Initial Investment vs. Lifelong Value

The perception of high cost is perhaps the most significant hurdle for laminated glass. While it's true that its initial price point is higher than monolithic annealed or tempered glass, a value-based analysis reveals a different story.

Market data suggests a broad price range for architectural laminated glass, typically from $100 to $600 per square meter, influenced by factors like glass thickness, interlayer type and thickness, and the complexity of any additional processing, such as curved glass or insulated glass unit assembly . For context, official construction cost indices list the installed cost for complex glass curtain wall systems at around $1290 per square meter, underscoring that the material cost is one component of a larger system .

The critical analysis lies in life-cycle costing. Consider these long-term value drivers:

Reduced Energy Costs: The inherent ability of the laminated glass interlayer to reduce solar heat gain translates to lower cooling loads and energy consumption for air conditioning. When combined in an insulated glass unit, the energy savings are compounded, leading to decades of lower utility bills that can offset the initial glazing premium .

Asset Protection: The 99.5% UV blockage dramatically slows the degradation and fading of expensive interior items like furniture, carpets, and draperies. The cost of replacing these items multiple times over the life of a building can far exceed the initial premium paid for the protective glazing.

Enhanced Security and Safety: The cost of a single break-in or an injury from broken glass can be immense, both financially and in human terms. Laminated glass acts as a robust deterrent and a reliable safety net, mitigating potential liabilities.

Durability and Low Maintenance: High-quality laminated glass, especially products with SGP interlayer, is known for its edge stability and resistance to yellowing or delamination over time, ensuring long-term performance with minimal maintenance .

When these factors are quantified, the Return on Investment (ROI) for laminated glass becomes clear. It is not merely a glazing product but an integral contributor to a building's safety, efficiency, durability, and operational cost profile.

The Future is Clear and Laminated

The evolution of laminated glass continues, driven by material science and a growing emphasis on sustainable, human-centric design. The development and adoption of high-performance interlayers like SGP are pushing the boundaries of what is possible, enabling more transparent, lighter, and stronger structures. The synergy of laminated glass with other technologies, particularly in insulated glass units, represents the future of high-performance building envelopes.

So, is laminated glass truly expensive? The evidence suggests that this is the wrong question. The right question is: Can you afford the long-term costs of not using it? When viewed through the lens of lifelong value, encompassing unparalleled safety, energy savings, asset protection, and design freedom, the answer becomes strikingly clear. The initial investment is not an expense but a wise and valuable investment in a building's future.