What Should You Focus on Most When Choosing Casement Windows in Terms of Materials and Workmanship?

The global glass industry is transforming, driven by technology and new consumer expectations. We see this in ultra-thin car windshields and energy-saving building facades, where the potential of glass is being redefined.

At the heart of this evolution, the casement window has emerged as a top choice for homeowners. It masterfully blends timeless aesthetics with modern functionality and sustainable performance.

As an industry leader, Jiangsu Guoxin Glass Co., Ltd. will guide you explore the key considerations below, from our material breakthroughs and precision engineering to how casement windows outperform sliding and pivot alternatives.

1. Material Innovation: Aluminium Windows Lead the Energy Efficiency Revolution

Casement windows, characterized by their outward-swinging design, are gaining traction for their superior ventilation and unobstructed views. However, the choice of frame material significantly impacts their performance, durability, and environmental footprint.

Aluminium Windows: The Lightweight Champion

Aluminium has emerged as a frontrunner in modern window design, particularly for casement windows. Its lightweight yet robust structure allows for slimmer profiles, maximizing glass area and natural light penetration. For instance, advanced aluminium casement windows feature sightlines as narrow as 65mm, offering panoramic views without compromising structural integrity.

From a thermal perspective, aluminium’s reputation as a heat conductor is being challenged by breakthroughs in thermal break technology. Modern aluminium frames incorporate insulating strips between interior and exterior panels, reducing heat transfer by up to 60% compared to traditional designs. This innovation positions aluminium casement windows as viable alternatives to wood or uPVC in energy-conscious projects.

Wood vs. Aluminium: A Balance of Tradition and Modernity

Wooden casement windows remain popular for their classic aesthetic and natural insulation properties. However, their susceptibility to warping, rot, and high maintenance requirements has led to a decline in market share. In contrast, aluminium windows require minimal upkeep, with powder-coated finishes resisting fading and corrosion for decades.

For regions with extreme climates, hybrid solutions combining aluminium exteriors with wooden interiors offer the best of both worlds: durability outside and warmth inside. Yet, the cost premium of such designs often limits their adoption to luxury segments.

Sliding vs. Swinging Windows: A Functional Comparison

While sliding windows excel in space-saving horizontal operation, casement windows (a subset of swinging windows) provide superior airtightness. When closed, their multi-point locking systems create a tighter seal than sliding counterparts, enhancing energy efficiency by up to 25%. This makes casement windows ideal for climates requiring stringent thermal performance.

2. Craftsmanship Precision: The Art of Engineering Perfection

The performance of casement windows hinges on meticulous craftsmanship, particularly in three areas: hardware durability, glass integration, and customization capabilities.

Hardware Durability: The Silent Guardian

Casement windows rely on hinges and operators to function smoothly over decades. Stainless steel hardware, resistant to corrosion and wear, is now standard in premium offerings. Advanced friction hinges allow windows to stay open at any angle, while concealed multi-point locks enhance security without compromising aesthetics.

Manufacturers are also adopting AI-driven quality control systems to detect micro-defects in hardware components. For example, laser scanning technology ensures hinge alignment within 0.1mm tolerance, preventing operational issues like window sagging or air leakage.

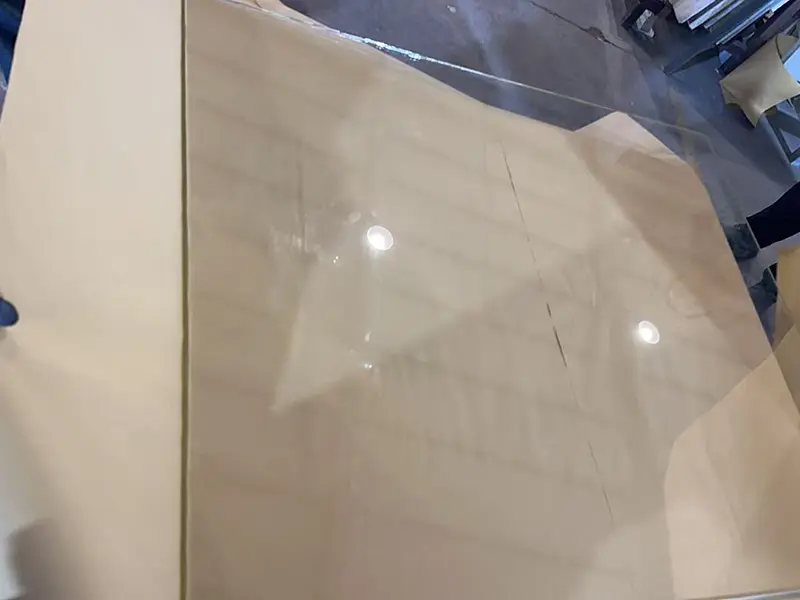

Glass Integration: From Clarity to Intelligence

Modern casement windows integrate low-emissivity (Low-E) coatings and argon-filled cavities to minimize heat loss. Double-glazed units with 20mm gaps achieve U-values as low as 0.8 W/m²K, meeting stringent passive house standards. For noise reduction, laminated glass with polyvinyl butyral (PVB) interlayers can attenuate sound by up to 40 decibels.

Innovations extend beyond insulation. Smart glass technologies, such as electrochromic coatings, enable users to tint windows dynamically, reducing glare and cooling loads. These features, once limited to commercial buildings, are now trickling into residential casement windows.

Customization Capabilities: Beyond Standard Sizes

While standard casement windows range from 14 inches to 36 inches in width and 24 inches to 72 inches in height, custom solutions are reshaping the market. Computer-aided design (CAD) software allows architects to specify curved or triangular casement windows for avant-garde projects. For instance, a recent project in the Netherlands featured casement windows with ±4mm tolerance on complex curves, demonstrating the industry’s ability to merge artistry with engineering.

3. Global Trends: Casement Windows in the Era of Sustainability

The glass industry’s shift toward circular economy principles is reshaping casement window production. Recycled aluminium, sourced from post-consumer scrap, now accounts for 75% of raw material in some factories, reducing carbon footprints by 90% compared to virgin aluminium.

Circular Design: Recyclability at the Core

Modular casement window systems enable easy disassembly and component reuse. For example, aluminium frames can be recycled indefinitely without losing strength, aligning with global zero-waste initiatives. Glass panes, though less recyclable, are increasingly being downcycled into insulation materials.

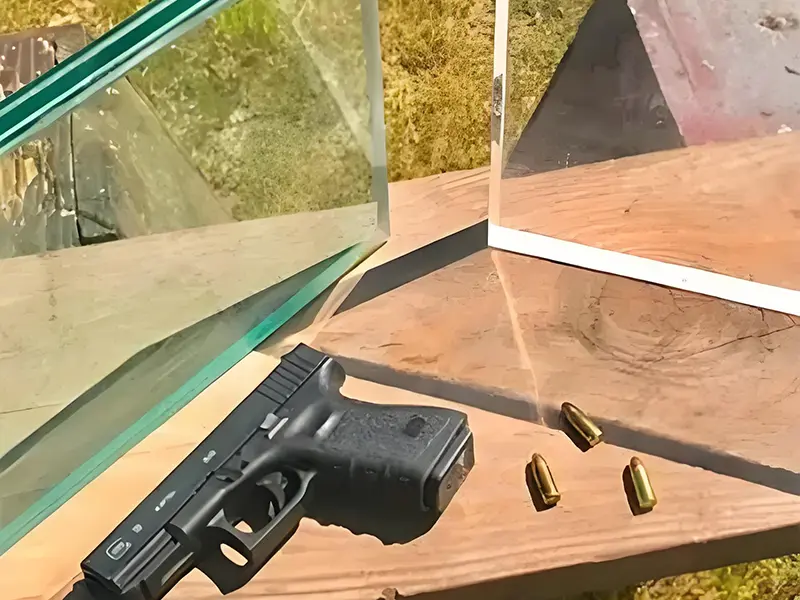

Regional Adaptations: Climate-Specific Solutions

In hurricane-prone regions, impact-resistant casement windows with laminated glass and reinforced frames are becoming mandatory. Conversely, in arid zones, windows with aerogel-filled cavities provide exceptional thermal insulation without compromising light transmission.

4. The Future of Casement Windows: AI and Robotics Redefine Manufacturing

The integration of Industry 4.0 technologies is revolutionizing casement window production. Robotic arms now handle glass cutting and frame assembly with sub-millimeter precision, reducing human error and material waste. AI algorithms optimize glazing configurations based on geographic location and building orientation, maximizing energy savings.

For instance, a factory in Europe uses machine learning to predict hardware wear patterns, scheduling maintenance proactively. Such innovations are slashing production costs by 30% while improving product longevity.

Conclusion: A Window of Opportunity

As the glass industry pivots toward sustainability and smart technologies, casement windows stand at the intersection of tradition and innovation. Aluminium frames, coupled with precision craftsmanship and climate-adaptive designs, are redefining their role in modern architecture. While sliding windows offer space efficiency, and traditional swinging windows provide familiarity, casement windows uniquely combine ventilation, aesthetics, and energy performance.

For homeowners and architects alike, the key lies in selecting materials that align with long-term sustainability goals and craftsmanship that ensures decades of reliable service. As the industry evolves, one truth remains: the right casement window is not just a product but a gateway to a brighter, greener future.